-

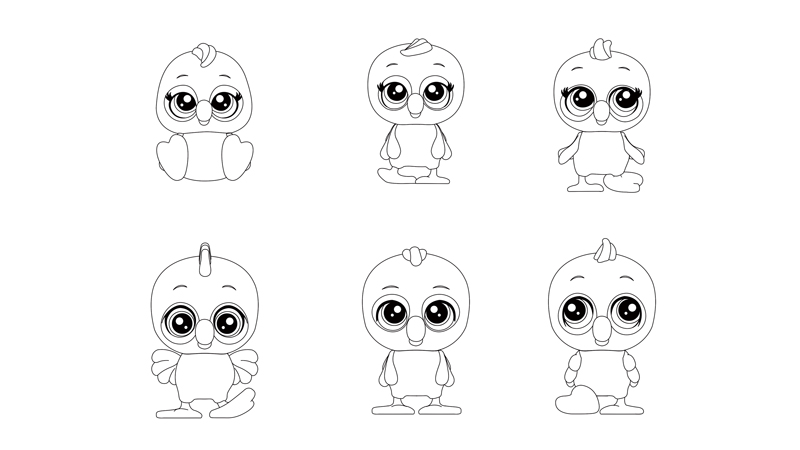

2D Design

From the start, 2D designs offer our clients a variety of innovative and attractive toy concepts. From cute and playful to modern and trendy, our designs cater to a wide range of styles and preferences. Currently, our popular designs include mermaids, ponies, dinosaurs, flamingos, llamas, and many more. -

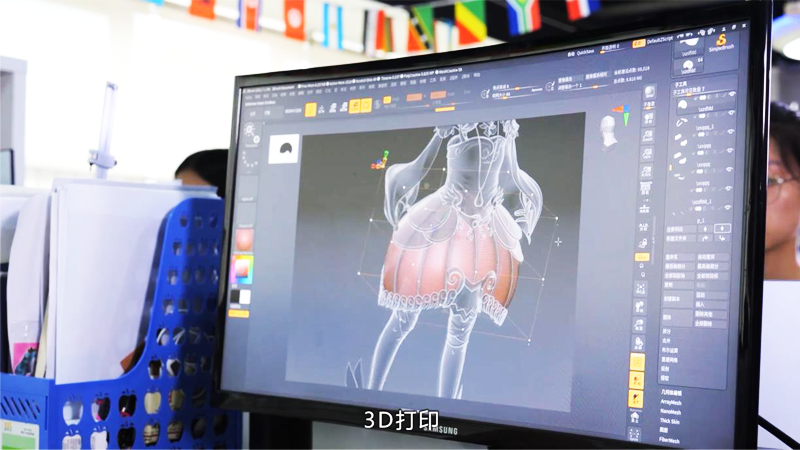

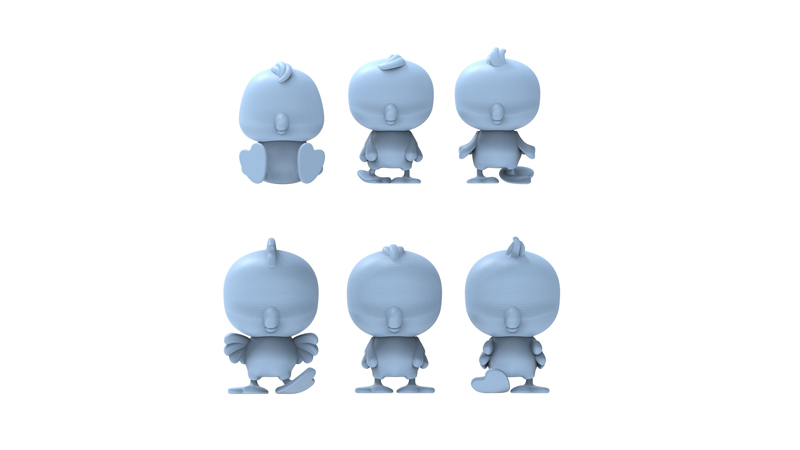

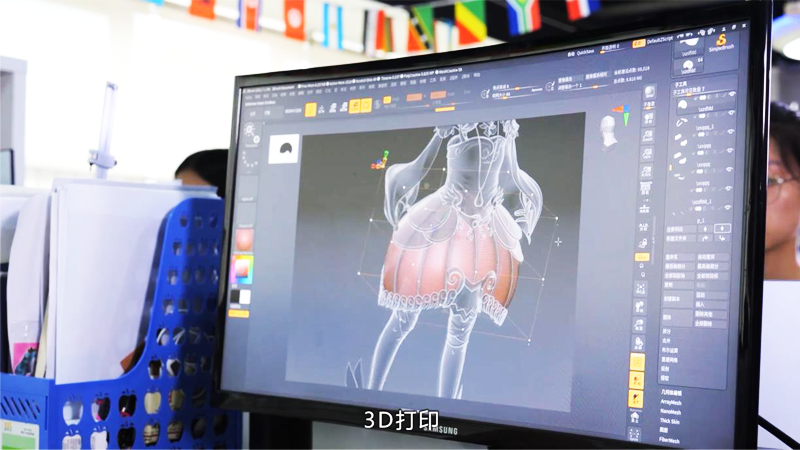

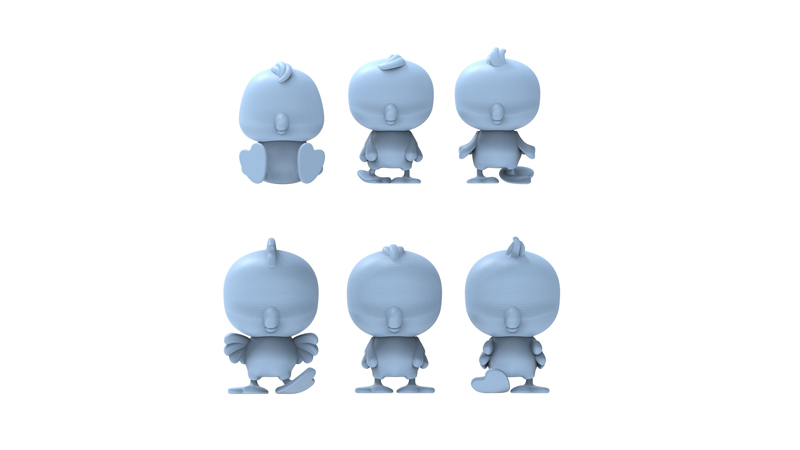

3D Moldeling

Taking advantage of professional software like ZBrush, Rhino, and 3DS Max, our expert team will transform multi-view 2D designs into highly detailed 3D models. These models can achieve up to 99% likeness to the original concept. -

3D Printing

Once the 3D STL files are approved by clients, we begin the 3D printing process. This is carried out by our skilled experts with hand-painting. Weijun offers one-stop prototyping services, allowing you to create, test, and refine your designs with unmatched flexibility. -

Mold Making

Once the prototype is approved, we begin the mold-making process. Our dedicated mold showroom keeps each mold set neatly organized with unique identification numbers for easy tracking and use. We also perform regular maintenance to ensure the molds’ longevity and optimal performance. -

Pre-Production Sample (PPS)

The Pre-Production Sample (PPS) is provided to the customer for approval before mass production begins. Once the prototype is confirmed and the mold is created, the PPS is presented to ensure the final product’s accuracy. It represents the expected quality of the bulk production and serves as the customer’s inspection tool. To ensure smooth production and minimize errors, the materials and processing techniques must be consistent with those used in the bulk product. The customer-approved PPS will then be used as the reference for mass production. -

Injection Molding

The injection molding process involves four key stages: filling, pressure holding, cooling, and demolding. These stages directly affect the quality of the toy. We primarily use PVC molding, which is ideal for thermoplastic PVC, as it is commonly used for most PVC parts in toy manufacturing. With our advanced injection molding machines, we ensure high precision in every toy we produce, making Weijun a reliable and trusted toy manufacturer. -

Spray Painting

Spray painting is a surface treatment process widely used to apply a smooth, even coating to toys. It ensures uniform paint coverage, including hard-to-reach areas like gaps, concave, and convex surfaces. The process includes surface pretreatment, paint dilution, application, drying, cleaning, inspection, and packaging. Achieving a smooth and uniform surface is crucial. There should be no scratches, flashes, burrs, pits, spots, air bubbles, or visible weld lines. These imperfections directly affect the appearance and quality of the finished product. -

Pad Printing

Pad printing is a specialized printing technique used to transfer patterns, text, or images onto the surface of irregularly shaped objects. It involves a simple process where ink is applied to a silicone rubber pad, which then presses the design onto the toy’s surface. This method is ideal for printing on thermoplastic plastics and is widely used for adding graphics, logos, and text to toys. -

Flocking

Flocking is a process that involves applying tiny fibers, or "villi", onto a surface using an electrostatic charge. The flocked material, which has a negative charge, is attracted to the object being flocked, which is grounded or at zero potential. The fibers are then coated with adhesive and applied to the surface, standing upright to create a soft, velvet-like texture.

Weijun Toys has over 20 years of experience producing flocked toys, making us experts in this field. Flocked toys feature strong three-dimensional textures, vibrant colors, and a soft, luxurious feel. They are non-toxic, odorless, heat-insulating, moisture-proof, and resistant to wear and friction. Flocking gives our toys a more realistic, lifelike appearance compared to traditional plastic toys. The added layer of fibers enhances both their tactile quality and visual appeal, making them look and feel closer to the real thing. -

Assembling

We have 24 assembly lines staffed with well-trained workers who efficiently process all finished parts and packaging components in sequence to create the final product - beautiful toys with exquisite packaging. -

Packaging

Packaging plays a crucial role in showcasing the value of our toys. We begin planning the packaging as soon as the toy concept is finalized. We offer a variety of popular packaging options, including poly bags, window boxes, capsules, card blind boxes, blister cards, clam shells, tin gift boxes, and display cases. Each packaging type has its advantages—some are favored by collectors, while others are perfect for retail displays or gifting at trade shows. Additionally, some packaging designs prioritize environmental sustainability or reduce shipping costs.

We are continuously exploring new materials and packaging solutions to enhance our products and improve efficiency. -

Shipping

At Weijun Toys, we ensure timely and secure delivery of our products. Currently, we primarily offer shipping by sea or railway, but we also provide customizable shipping solutions tailored to your needs. Whether you require bulk shipments or expedited delivery, we work with trusted partners to ensure your order arrives on time and in perfect condition. Throughout the process, we keep you informed with regular updates.

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top