Welcome to Weijun Toys Factory Tour

Discover the heart of Weijun Toys through our Factory Tour! With over 40,000+ square meters of production area and a team of 560 skilled workers, we take pride in showcasing how our high-quality toys come to life. From advanced manufacturing processes and in-house design teams to strict quality control measures, our factory represents the perfect blend of innovation and craftsmanship. Join us as we take you behind the scenes to explore how we transform creative ideas into exceptional products trusted by global brands and businesses.

Factory Tour

Watch our Factory Tour video for a virtual visit to Weijun Toys and experience the expertise behind toy manufacturing. Discover how our advanced facilities, skilled team, and innovative processes come together to create high-quality, safe custom toys.

200+ Industry-Leading Machines

In our Dongguan and Ziyang factories, production is driven by over 200 cutting-edge machines, engineered for precision, efficiency, and versatility. These include:

• 4 dust-free workshops

• 24 automated assembly lines

• 45 injection molding machines

• 180+ fully automatic painting and pad printing machines

• 4 automatic flocking machines

With these capabilities, we can manufacture a wide range of toy products, including action figures, plush toys, electronic toys, and other collectible figures, all tailored to meet clients' specific needs and design preferences. Our advanced technology ensures we deliver high-quality, custom products efficiently and at scale.

3 Well-Equipped Testing Laboratories

Our three advanced testing laboratories ensure every product meets the highest safety and quality standards. Equipped with specialized devices like:

• Small parts testers

• Thickness gauges

• Push-pull force meters, etc.

We conduct rigorous tests to guarantee the durability, safety, and compliance of our toys. At Weijun Toys, quality is always our priority.

560+ Skilled Workers

At Weijun Toys, our team of over 560 skilled workers includes talented designers, experienced engineers, dedicated sales professionals, and highly trained workers. With their expertise and commitment, we ensure every toy is crafted with precision and attention to detail, delivering top-quality products to meet our clients' needs.

A Quick View of The Production Process

Get an inside look at how Weijun Toys transforms creative ideas into high-quality products. From initial design concepts to final assembly, our streamlined production process ensures every toy meets the highest standards. Explore each step of the journey and see how our advanced machines and skilled team work together to bring your vision to life.

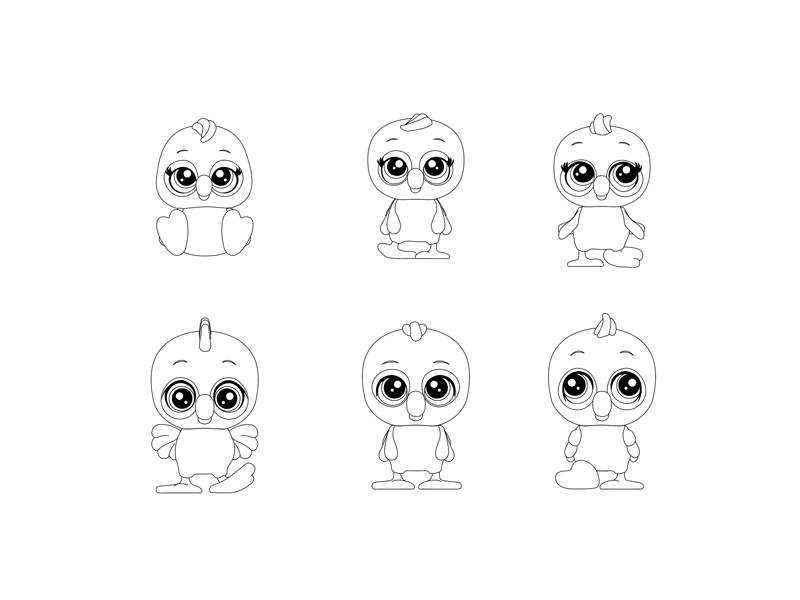

Step 1

2D Design

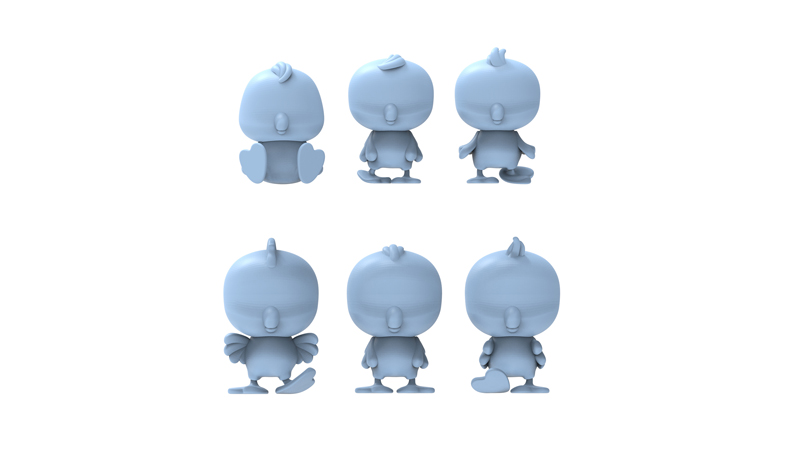

Step 2

3D Modeling

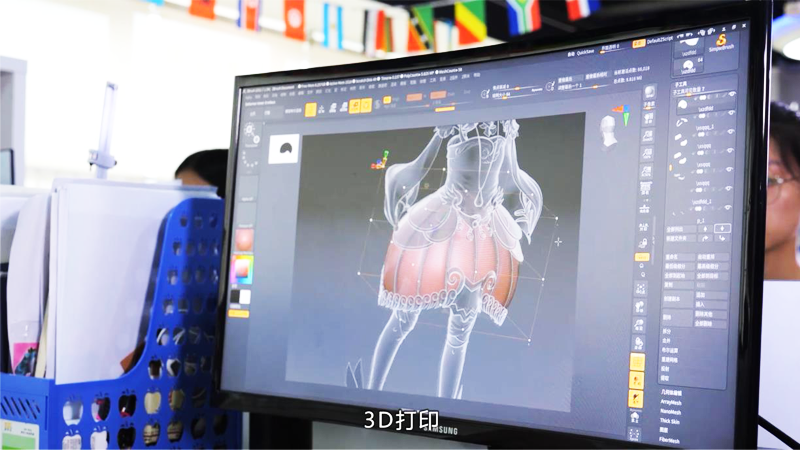

Step 3

3D Printing

Step 4

Mold Making

Step 5

Pre-Producttion Sample (PPS)

Step 6

Injection Molding

Step 7

Spray Painting

Step 8

Pad Printing

Step 9

Flocking

Step 10

Assembling

Step 11

Packaging

Step 12

Shipping

Let Weijun Be Your Trusted Toy Manufactuer Today!

Ready to produce or customize your toys? With 30 years of expertise, we offer OEM and ODM services for action figures, electronic figures, plush toys, plastic PVC/ABS/vinyl figures, and more. Contact us today to schedule a factory visit or request a free quote. We'll handle the rest!