Custom Action Figures

From prototype to product, we offer one-stop action figure manufacturing solutions, including plastic ABS/PVC action figures, plush action figures, anime action figures, and more.

At Weijun Toys, we bring 30 years of expertise to the production of custom action figures, offering a wide range of options including plastic action figures (ABS/PVC), plush action figures, anime figures, and action figure accessories. Our comprehensive manufacturing solutions cover every stage of production, from concept design and prototyping to mass production and quality control. Whether you need realistic figures with intricate details, customizable accessories, or figures featuring special effects, we will bring your vision to life. We ensure that every product meets your exact specifications, delivering exceptional quality and outstanding results every time.

If you want to start with market-ready toys, please explore and choose from our full action figure product catalog >>

FAQ About Action Figures Manufacturing

At Weijun, mass production typically takes 40-45 days (6-8 weeks) after prototype approval. That means once the action figure prototype is approved, you can expect your order to be ready for shipment within 6 to 8 weeks, depending on the complexity and quantity of the order. If accessories are included, the production time may be longer. We work efficiently to meet deadlines while ensuring the highest quality standards.

We typically require a minimum order of 3,000 units for action toy figures. However, if you have specific customization needs, the MOQ (Minimum Order Quantity) is flexible and can be negotiated. Our marketing team is ready to collaborate with you to develop personalized solutions that align with your requirements, budget, and production timeline.

With decades of experience in toy figure customization, we offer a range of options to bring your vision to life. If you have a prototype and specifications for your action figures and accessories, we can follow them precisely. If not, we can provide tailored solutions for your needs, including:

• Rebranding: Custom logos, cards, etc.

• Designs: Custom number of joints, colors, sizes, accessories, and finishing techniques.

• Packaging: Options such as PP bags, blind boxes, display boxes, capsule balls, surprise eggs, and more.

The total cost of manufacturing action figures depends on several key factors. Whether you need us to design figures from scratch or produce them based on your designs and specifications, Weijun Toys can tailor the process to fit your budget and project requirements.

Factors that impact the cost include:

• Character design & prototyping (if applicable)

• Number of joints

• Painting

• Figure sizes

• Quantity

• Sample fees (refundable after mass production confirmation)

• Packaging (PP bags, display boxes, etc.)

• Freight & delivery

Feel free to reach out and discuss your project with our experts. We'll provide personalized service to meet your goals. This is how we've stayed ahead of the industry for 30 years.

Shipping costs are charged separately. We partner with experienced shipping companies to offer flexible delivery options based on your needs, including air, sea, train, and more.

The cost will vary depending on factors such as the delivery method, order quantity, package size, weight, and shipping distance.

Who We Work With

√ Toy Brands: Delivering customized designs to enhance your brand portfolio.

√ Toy Distributors/Wholesalers: Bulk production with competitive pricing and fast turnaround times.

√ Capsule Vending Machine Operators: Compact, high-quality mini figures perfect for vending machines.

√ Any businesses requiring large volumes of action figures.

Why Partner With Us

√ Experienced Manufacturer: Over 20 years of expertise in OEM/ODM toy production.

√ Custom Solutions: Tailored designs for brands, distributors, and vending machine operators.

√ In-House Design Team: Skilled designers and engineers bring your vision to life.

√ Modern Facilities: Two factories in Dongguan and Sichuan, spanning over 35,000m².

√ Quality Assurance: Strict testing and compliance with international toy safety standards.

√ Competitive Pricing: Cost-effective solutions without compromising quality.

How Are Action Figures Manufactured at Weijun Factory?

Weijun operates two modern factories, one in Dongguan and the other in Sichuan, covering a total area of 43,500 square meters (468,230 square feet). Our facilities feature advanced machinery, a skilled workforce, and specialized environments to ensure efficient and high-quality production:

• 45 Injection Molding Machines

• Over 180 Fully Automatic Painting and Pad Printing Machines

• 4 Automatic Flocking Machines

• 24 Automatic Assembly Lines

• 560 Skilled Workers

• 4 Dust-Free Workshops

• 3 Fully Equipped Testing Laboratories

Our products can meet high industry standards, such as ISO9001, CE, EN71-3, ASTM, BSCI, Sedex, NBC Universal, Disney FAMA, and more. We're happy to provide a detailed QC report upon request.

This combination of advanced facilities and strict quality control ensures that every action figure we produce meets the highest standards of quality and durability.

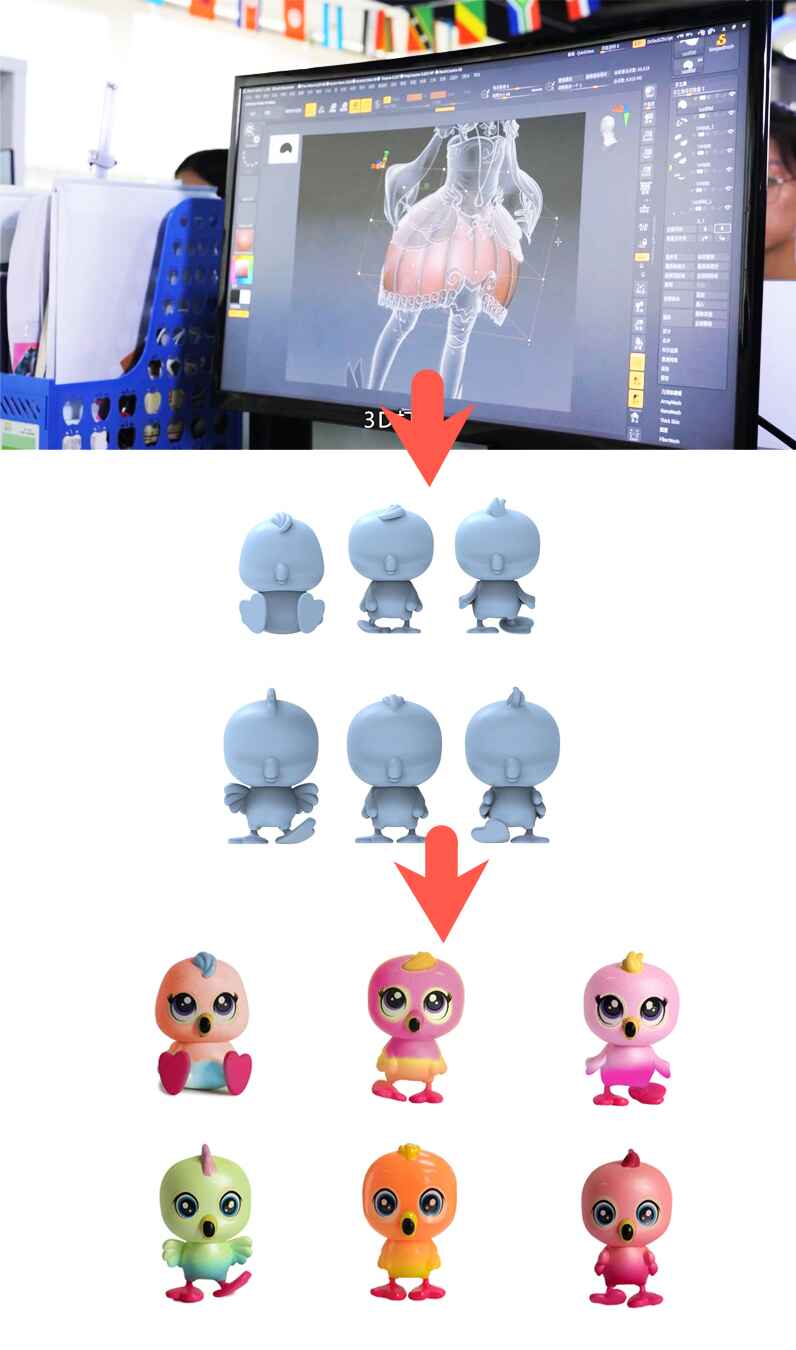

Now, let's show you the action figure manufacturing process at the Weijun factory.

Step 1: Action Figure Prototyping

Prototyping is the foundation of creating high-quality custom action figures. We work closely with you to bring your ideas to life, ensuring every detail meets your expectations before mass production begins.

1) Concepts & Design

We start with rough sketches and finalize the design with detailed turnarounds and color concepts, ensuring every feature is considered.

2) Prototype Modeling & Refinement

We sculpt each body part and accessory, either by hand or digitally, creating an unpainted prototype for your review. Once approved, we refine the prototype for production readiness.

3) Molding

After your approval, we create molds for mass production.

4) Painting

The prototype is painted to create a "paint master," which serves as the guide for production. We then produce test toys to verify function and quality.

5) Final Approval

Before mass production, we send final samples for your approval to ensure that everything meets your quality expectations.

Step 2: Action Figure Manufacturing

After you approve the sample, we start the mass production process at our factory. Here's the streamlined overview of our action figure manufacturing process.

1) Action Figure Parts Production

Through injecting molding, we make every part of the figure and accessories.

2) Action Figure Painting

After parts are cast, they undergo detailed painting. We use both spray painting machines and hand painting to achieve the perfect finish.

3) Action Figure Assembly & Packaging

The painted parts are carefully assembled and placed in their selected packaging, ready for shipment.

Custom Action Figures: Everything You May Want to Know

In today's market, action figures are not just toys - they're collectibles, limited-edition items, and powerful brand tools. The characters of action figures can come from movies, literature, or original concepts. But how to turn a character into an actionable toy figure? What should be considered from the very beginning? We will show you the process of creating action figures from concept to products at the Weijun factory.

#1 Action Figure Materials

Weijun has 30 years of action figure manufacturing experience. It's hard to say what material is the best to make action figures because different materials offer different flexibility, realism, strength, and durability. Below are the most commonly used materials in our factories:

• PVC (Polyvinyl Chloride): Best for standard action figures, collectibles, and toys.

• ABS (Acrylonitrile Butadiene Styrene): Best for high-quality, sturdy figures or accessories that require a bit more strength.

• POM (Polyoxymethylene) / Acetal: Best for joints and movable parts that need precision and smooth articulation.

• Additional Materials: We can integrate a variety of materials into your toy, including magnets, electronics, resin, plush, fabrics, metal, and more.

#2 Action Figure Size

The size of an action figure affects its articulation, level of detail, and overall marketability.

• Small-Scale Figures: 2" to 3" figures for collectibles or miniatures

• 3.75" Figures: Offer a compact size with enough details

• 6" Figures: Offer a balance of detail and articulation

• 12" Figures: Offer extra space for intricate details, realistic clothing, and accessories

• 18" or Larger Figures: Large size or even life-size figures for display or promotional use

#3 Action Figure Joints

The joints and articulation points of an action figure play a critical role in its functionality, poseability, and overall appeal.

Common Articulation Points:

• Head/Neck Joint: Rotation or tilting

• Shoulder Joint: Full arm movement (up, down, around

• Elbow Joint: Bending

• Wrist Joint: Rotation or bending

• Torso/Waist Joint: Twisting or bending

• Hip Joint: Legs movement

• Knee Joint: Leg bending

• Ankle Joint: Rotation or pivot

Advanced Articulation Points:

• Ball-and-Socket Joints: Multi-directional movement

• Double-Jointed Joints: Deeper bends

• Butterfly Joints: Inward and outward arm movement

• Ab Crunch Joint: Torso flexibility

• Thigh and Bicep Swivels: Adjusting angles

At Weijun, we can make action figures with a varied number of joints:

• One Joint: A rotating head

• 3 Joints: Rotating head and both arms

• More Joints: More flexibility

We work to seamlessly integrate the engineering and joints into the figure's design, ensuring they are as discreet as possible for a cleaner, more realistic look.

#4 Action Figure Accessories

At Weijun Toys, we can make a wide range of custom action figure accessories tailored to your specific design needs. We work with a variety of materials, including plastics, fabric, cardboard, metal, magnets, and more.

• Weapons

• Clothing and armor

• Vehicles and playsets

• Interchangeable heads, hands, and bodies

• Other gear and equipment

No matter the materials or the number of accessories, we ensure they are perfectly compatible with your figures, providing both functionality and design cohesion.

#5 Action Figure Painting

Painting is the key to transforming a molded plastic figure into a lifelike representation. We offer full customization for your action figure paint designs, including colors, patterns, and intricate details. The mass production at Weijun Toys ensures precise and consistent results across large volumes, maintaining the highest quality standards for every figure.

#6 Action Figure Branding

At Weijun Toys, branding and logos can be sculpted, engraved, painted, or imprinted directly onto the surface of the action figure or its accessories, ensuring your brand is prominently featured.

#7 Action Figure Packaging

At Weijun Toys, we offer a range of custom action figure packaging solutions, whether you are planning for display, gifting, or retail shelves. Here are the packaging options we provide:

• Transparent PP Bag: Showcases your figure while keeping it protected

• Blind Bag: Surprise collectibles

• Blind Box: Collectible series

• Display Box: Retail environments

#8 Action Figure Quality Control

At Weijun Toys, we maintain strict quality control across all stages of production. Our facilities are equipped with advanced test laboratories, where we conduct a variety of tests to ensure safety and durability. All samples are sent to clients for review to ensure they meet your expectations before full production begins. We adhere to international quality standards, conducting articulation tests, stress tests on figures and packaging, and transit and drop tests to simulate real-world conditions. This guarantees that every action figure is safe, durable, and ready for retail.

Let Weijun Be Your Trusted Action Figure Manufacturer!

Ready to create custom action figures? With about 30 years of experience, we specialize in crafting customizable action figures for toy brands, distributors, wholesalers, and more. Whether you're looking to produce plastic action figures, plush action figures, or action figure accessories, simply request a free quote, and we'll take care of the rest.